Shapeoko 2 - Experimentations

Software

- cncjs

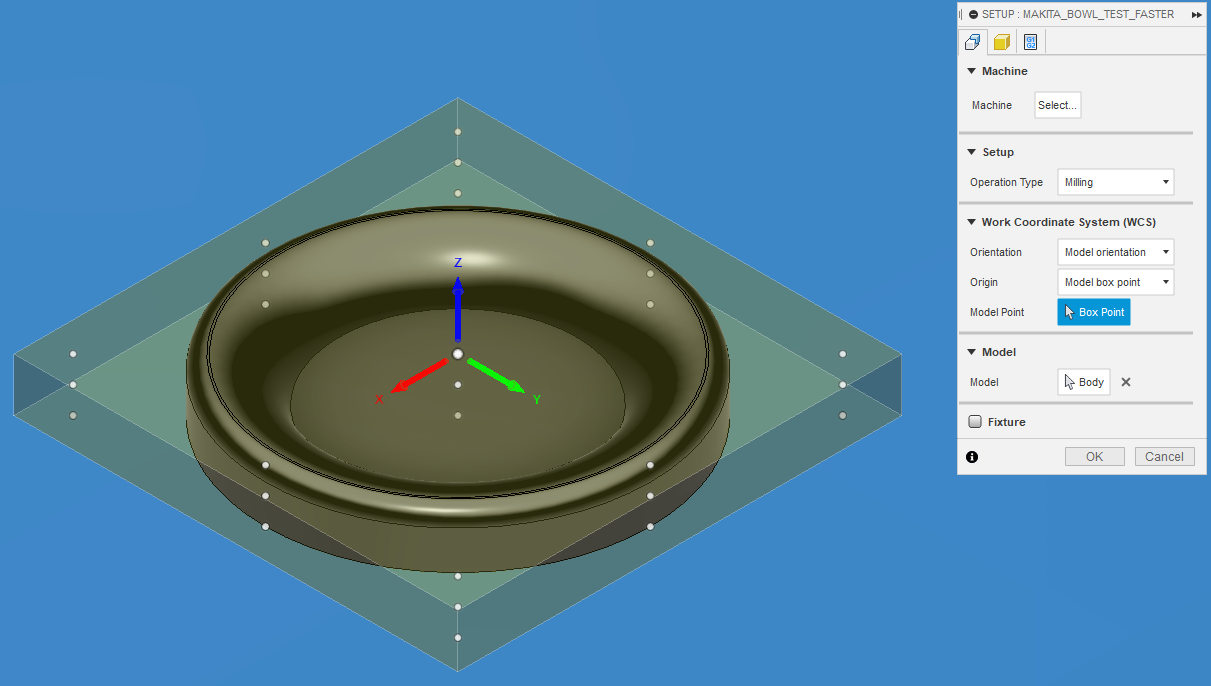

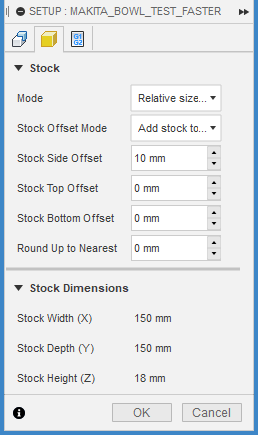

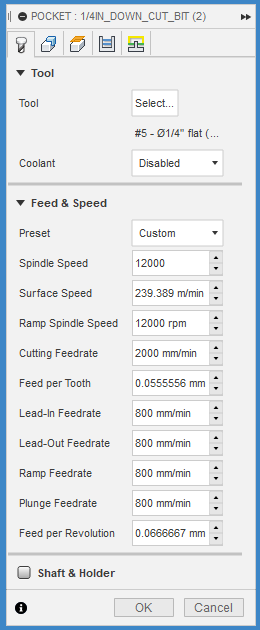

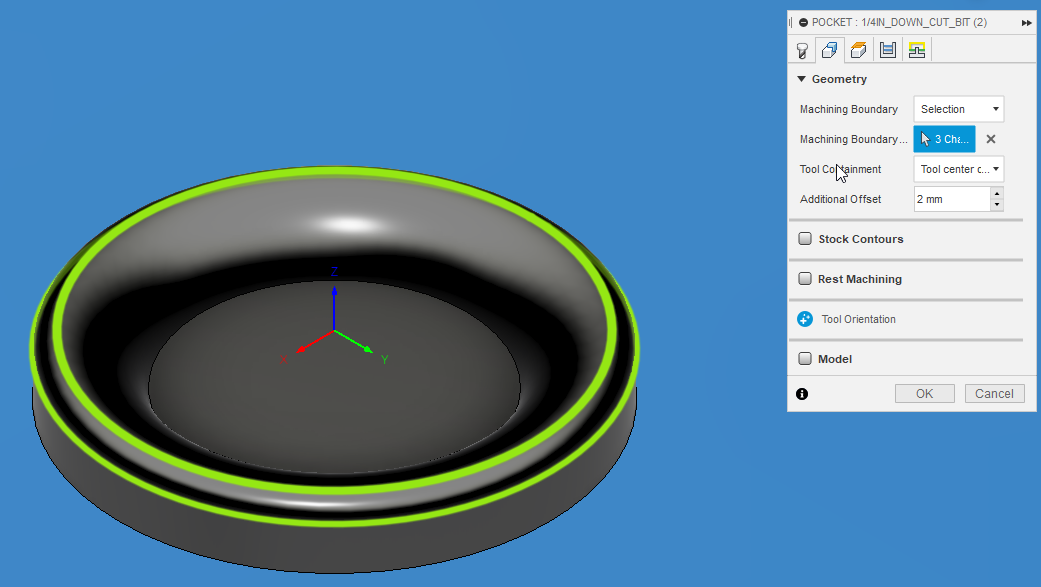

- Fusion 360

Hardware

- Shapeoko 2

- (Bit #1) 1/8 (3.175mm) shaft 3 flutes end mill

- (Bit #2) 1/8 (3.175mm) shaft PCB milling end mill

- Mastercraft Rotary Tool (54-4770-4)

- Makita RT0701C

- (Bit #3) 1/4 (6.35 mm) shaft straight 1/4 up cut

- (Bit #4) 1/4 (6.35 mm) shaft round 3/8

- (Bit #5) 1/4 (6.35 mm) shaft round nose 1/2

- Spindle 500W

Notes

| NC File | Bit | RPM | Cutting Feedrate | Lead in/out Feedrate | Step-down | Tool | Material | Operation | Date | Success | Images | | --------------------------------------------------------------------------- | ------------------- | ----- | ---------------- | -------------------- | ---------- | -------------- | --------- | ----------- | ---------- | ---------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------- | ------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------- | --- | | sides_batch_1_1001_3mm.nc | #1 | 25000 | 635 mm/min | 400 mm/min | 1 mm | 54-4770-4 | Pine | 3D Adaptive | 2021-09-29 | No, the bit was deviated from the path. | | sides_batch_1_v2_1001_3mm.nc | #1 | 25000 | 420 mm/min | 100 mm/min | 1 mm | 54-4770-4 | Pine | 3D contour | 2021-09-29 | It works, but be sure that the stock is well attached to the waste board; also it is kind of hard on the machine, I'll try something else. |

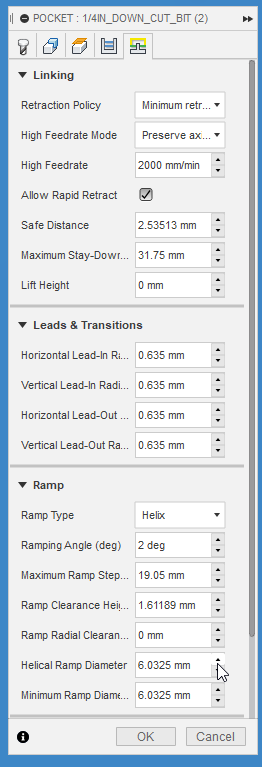

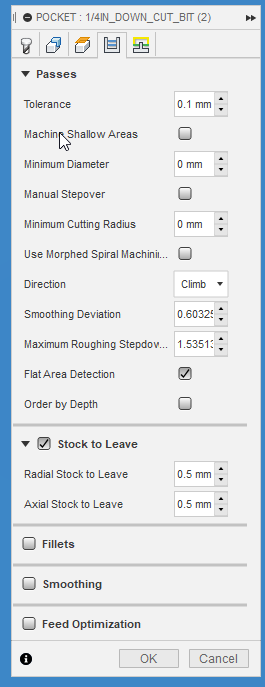

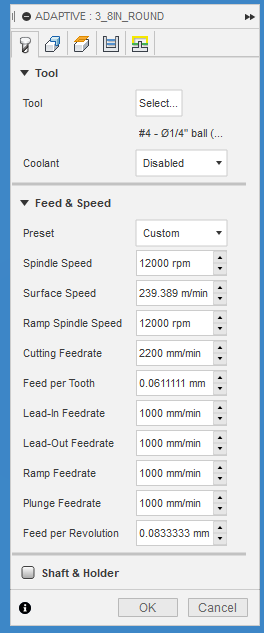

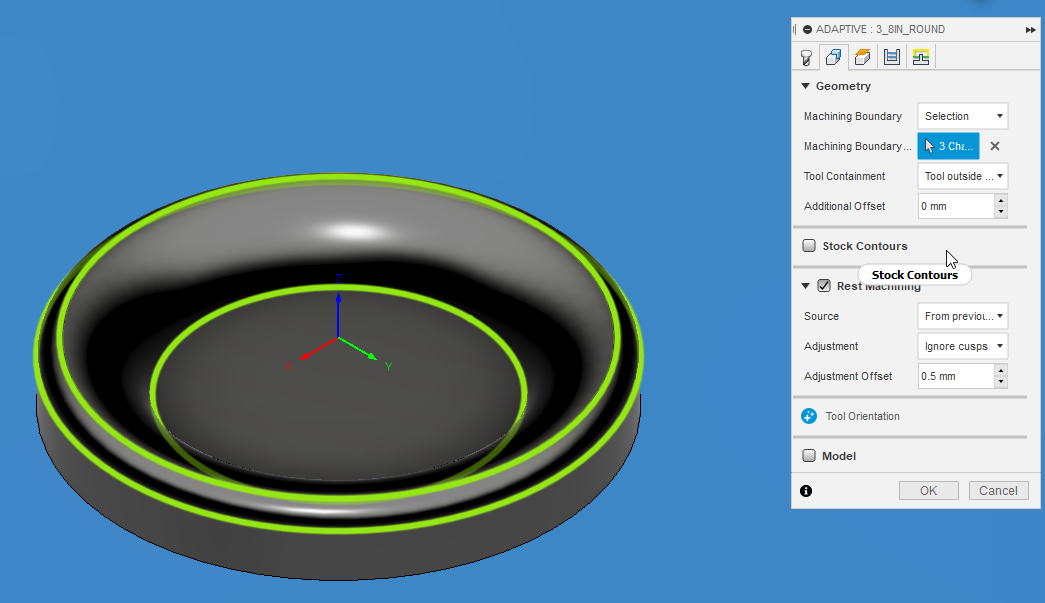

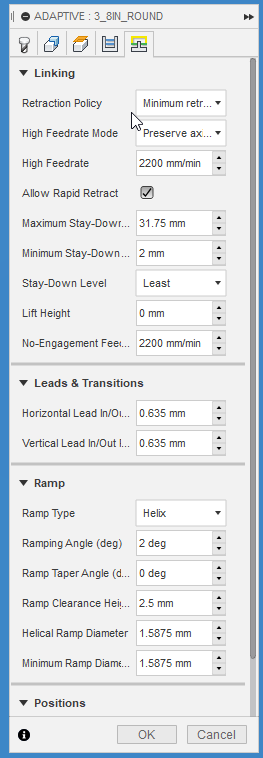

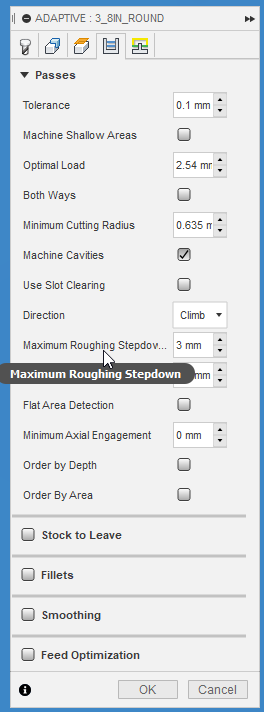

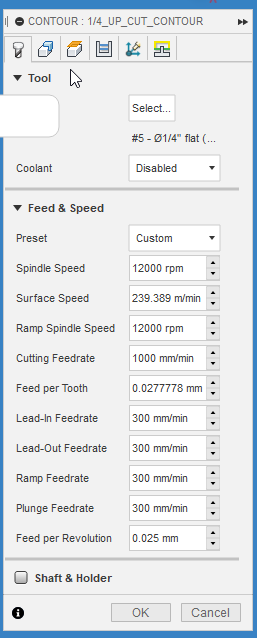

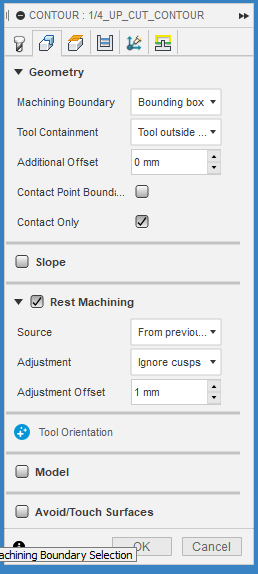

| step1_plate_first_attempt_1000mm_3mm_MDF_34in_bit12in_round_node_rotated.nc | #5 | 10000 | 1000 mm/min | 500 mm/min | 3mm | Spindle 500W | MDF 3/4in | Pocket 3D | 2021-10-17 | Yes, it is quite fast ~20min to complete. The ramp used is Helix | PUT IMAGES HERE |

Notes found on internet

- [Not Tested] Smaller passes 0.2 mm using a higher feedrate 1000-1200 mm/min

- [Not Tested] Passes of 0.7 mm using a feed rate of 420 mm/min with an RPM of 6000, plunge rate of 100 mm/min

Tips

- Be sure that the depth of your stock is the same everywhere

- Use a planer (I don't have one and it is hard to define the 0 properly)

- Attach your stock properly

- Using double side tape

- Using super glue

- Using Clamps

- Level your bed

- let at least 10 mm around your stock to be able to clamp without touching the tool

- Don't cut through the first time, I leave about a 1-2 mm

- Try to set your zero at the middle of the piece to avoid offset when using the edge with a small diameter